– Pre Hardened –

ElmedurB2

Precipitation hardened alloy with good thermal conductivity and high hardness.

Chemical Composition

| CODE | DIN | Be | Ni+Co | Cu |

|---|---|---|---|---|

| CuBe2 CW101C | 2.1247 | 2,0 | 0,4 | balance |

Material Properties

- Precipitation hardened alloy with good thermal conductivity and high hardness.

- Not suitable for case hardening or nitriding.

Applications

- Plastic blow and injection moulds

- Inserts in steel tools on spots requiring higher cooling rates. Due to a high tensile strength also suitable for inserts with a high ratio of length/cross section

- Nozzles and needles for hot runner systems

- Cooling inserts in moulds and ingot moulds

Heat Treatment

| HEAT TREATMENT | TEMPERATURE | TIME | COOLING | HARDNESS HV |

|---|---|---|---|---|

| Solution annealing | 750-800°C | 1/2 h | Water | max. 210 |

| Precipitation hardening | 325°C | min 2 h | Water or air | c. 400 |

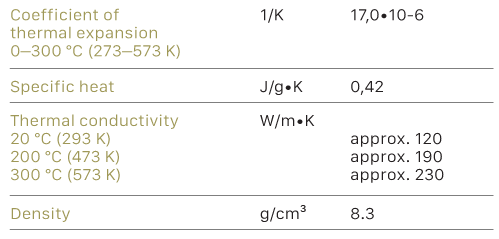

Physical Properties (precipitation hardened)

Machining and Application Conditions

| MILLING | TURNING | DRILLING | HEAT TREATMENT | NITRIDING | POLISHABILITY |

|---|---|---|---|---|---|

| + | + | + | - | - | + Very good |

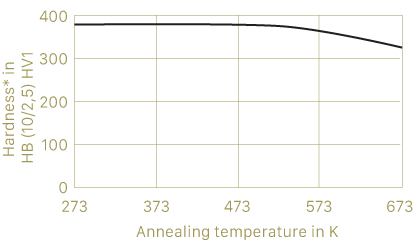

Resistance to Tempering of Elmedur B2