– Pre Hardened –

2738 VEXtra

Also known as P20 + Ni plastic mold steel suitable for rapid mold production, it is available in two hardness levels, one standard 33 HRc and the other (High Hard) 36 HRc.

Chemical Composition

| NO | DIN | AISI | C | Si | Mn | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| V'1.2738 | 40CrMnNiMo8-6-4 | P20+Ni | 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | Max 0,02 | Max 0,005 | 1.80-2.10 | 0.15-0.25 | 0.90-1.20 |

Material Properties

- Distribution of uniform hardness throughout the cross section

- Homogeneous internal structure with sufficient cleaning

- Good polishability

- Good designing ability

- Weldability

- Good workability despite pre-hardened

- It has good nitriding properties

- Recommended usage hardness is delivery hardness

Applications

- It can be used as a core in all kinds of plastic injection molds of polymers up to A1 surface quality and not containing more than 10% reinforcement: Automotive trim molds, panels in white goods, etc

- As mold holder, hot runner distributor

- In extrusion molds of non-corrosive plastics

- In the barrels of extrusion presses

- Machine parts, wear plates

- Plastic pressing is used in compression molds

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 710-740°C |

| Stress Relieving | 550-600°C |

| Hardening | 840-870°C |

| Tempering | 600-680°C |

Physical Properties

| 20°C | 100°C | 350°C | 700°C | |

|---|---|---|---|---|

| Elastic Modulus [kN/mm²] | 212 | 207 | 194 | - |

| Thermal Expansion Coefficient [10ˉ6/K] | - | 11,7 | 13,3 | 14,0 |

| Thermal Conductivity [W/mK] | 35.2 | 35.7 | 35.5 | - |

| Toughness | 32 | - | - | - |

| Strength [N/mm²] | 937 | - | - | - |

Delivery Condition

The hardness level of the pre-Hardened grades is shown as below. The hardness’ guaranteed is only on the surface of the blocks. The hardenability of the 2738 is not perfect and the hardness lost at core is around 3-4 Hrc.

| MATERIAL | BRINELL HARDNESS | HRc | N/mm2 |

|---|---|---|---|

| 1.2738 | 280-320 | 30-34 | 965-1085 |

| 1.2738 HH | 320-350 | 34-38 | 1085-1200 |

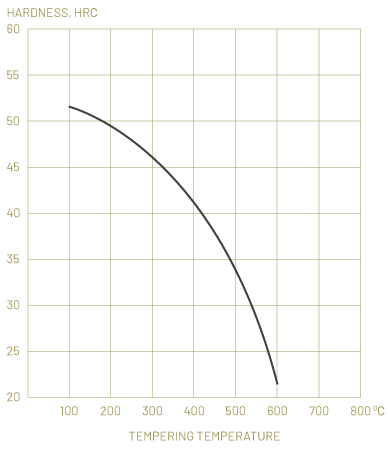

Tempering Graph