ZAPP Z M48 PM

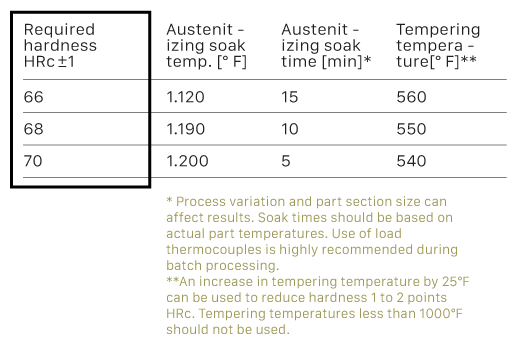

ZAPP Z M48 PM is an ultra high performance HSS produced by powder metallurgy methods that can be heat treated to a maximum attainable hardness of HRc 68-70.

Chemical Composition

| NO | DIN | C | Cr | Mo | V | W | Co |

|---|---|---|---|---|---|---|---|

| Z M48 PM | Special Alloy | 2,00 | 4,00 | 5,00 | 5,00 | 10,00 | 9,00 |

Material Properties

- Very high hardness 68-70 HRc

- Very good abbrasive wear resistance

- Very good adhasive wear resistance

- Very high compression strength

- High toughness

- Suitable for high temperature tempering

- Suitable for coating with appropriate heat treatment

- Suitable for sub-zero treatment

Uygulamaları

- Form tools

- Gear tools

- Broaches

- Misc. cutting tools

- Precision wear parts

- Powder compaction tooling

- Roll forming tools

- Punches and dies

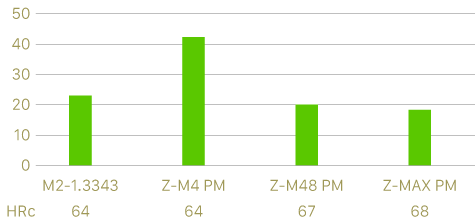

Relative Toughness

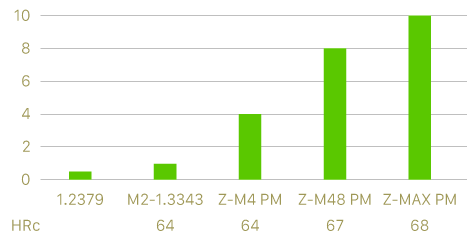

Wear Resistance

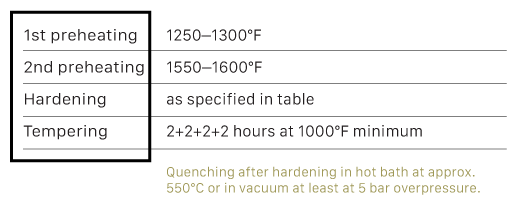

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Annealing | Heat uniformly in a protective atmosphere (or vacuum) to 1600°F (870°C) and soak for 2 hours. Slow cool 30°F (15°C) per hour until 1000°F (540°C). Parts can then be cooled in air or furnace as desired. Hardness expected is BHN 245 -275. |

| S tress relieving (soft) | Heat uniformly to 1100 -1300°F (595 -700°C), soak for 2 hours, and cool in air or furnace. |

Heat Treatment in Structions

Delivery Conditions

255- 277 HB

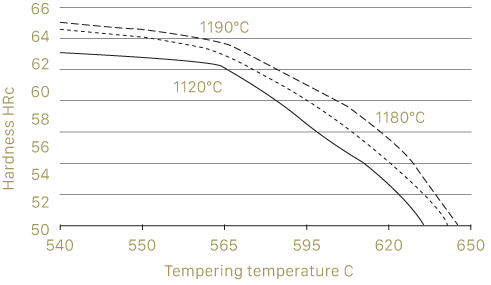

Tempering Graph