TC-379

One of the most common cold work tool steel, good combination of high wear resistant and Good enough toughness.

Chemical Composition

| NO | DIN | C | Si | Cr | Mo | V | Mn | S | P |

|---|---|---|---|---|---|---|---|---|---|

| V’1.2379 | X153CrMoV12 | 1,45-1,60 | 0,10-0,60 | 11,00-13,00 | 0,70-1,00 | 0,70-1,00 | 0,20-0,60 | Max 0,05 | Max O,025 |

Material Properties

- High abrasive wear resistant.

- Good adhesive wear resistance.

- High compressive strength.

- Good enough toughness for common blanking applications.

- Good for high temperature tempering.

- Very good coating results if the appropriate heat treatment is applied.

- Suitable for sub-zero degree operations.

- Good dimensional stability during heat treatment.

Applications

- Forming, blanking dies

- Deep drawing dies,

- Shearing dies and tools.

- Profile rolls and tools.

- Die and punches manufacturing.

- Stone crushing balls.

- Industrial knives.

- Hand knives.

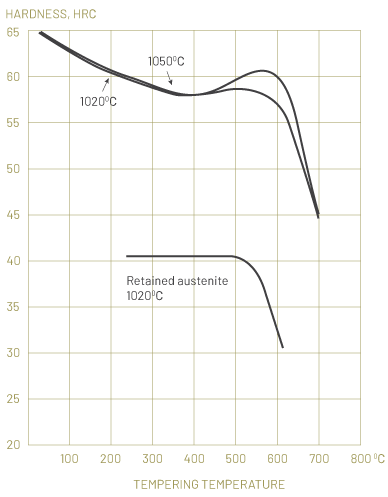

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 820-850°C |

| Stress Relieving | 600-650°C |

| Hardening | 1000-1050°C |

| Tempering | 500-560°C |

Physical Properties

| 20°C | 100°C | 200°C | 300°C | 350°C | 400°C | |

|---|---|---|---|---|---|---|

| Elastic Modulus [kN/mm²] | 210 | - | - | - | - | - |

| Thermal Expansion Coefficient [10ˉ6/K] | - | 10,5 | 11,5 | 11,9 | - | 13,0 |

| Thermal Conductivity [W/mK] | 16,7 | - | - | - | 20,5 | - |

Delivery Condition

255 HB, Soft Annealed.

Tempering Graph