TC-360V

TC-360V is an air-hardening special steel with excellent toughness and resistance to compression and wear for applications, where these properties of ledeburitic chromium steels are not enough.

Chemical Composition

| C | Si | Cr | Mo | V | W |

|---|---|---|---|---|---|

| 1,15 | 1,00 | 8,00 | 1,50 | 2,40 | 1,20 |

Material Properties

- Very good corrosion resistance.

- Good wear resistance.

- Excellent polishability and surface finish.

- Good machinability.

- Heat treatable up to 52 HRc.

- Limited texturing and nitriding ability.

- Good coating ability.

- High wear resistance.

Applications

- Cutting

- Blanking and punching tools

- Stamping tools,

- Shear blades

- Thread rolling dies

- Cutters for plastic

- Cable recycling

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Hot forming | 1050-850°C/slow cooling in furnace |

| Soft annealing | 840-870°C/slow cooling in furnace |

| Brinell-hardness after annealing | max. 250 HB |

| Stress relieving | 650°C/slow cooling in furnace |

| Preheating to hardening | 850°C |

| Hardening | 1040-1090°C |

| Quenching | air, oil |

| Tempering | minimum 3 times |

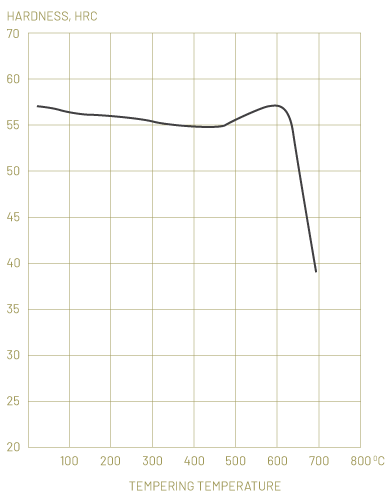

Tempering Graph