TC-358

Cold work tool steel suitable for surface hardening and car hoods forming dies.

Chemical Composition

| NO | DIN | C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|---|---|

| V’1.2358 | 60CrMoV18-5 | 0,58-0,62 | 0,20-0,50 | 0,70-0,90 | Max 0,025 | Max 0,05 | 4,30-4,70 | 0,40-0,60 | 0,20-0,30 |

Material Properties

- High Toughness.

- Very good hardenability.

- Good flame and induction hardenability

- Good weldability.

- Easy for maintenance.

- Good Polishability.

- Hardness up to 58 HRc.

- Simple heat treatment.

- Fast forming die making

Applications

- Car body dies

- Forming dies.

- Deep drawing dies.

- Blanking and forming segments.

- Segmented molds.

- Punches with complex geometry

- Shearing blades, tread rolls

- Cutting blades.

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 820-860°C |

| Stress Relieving | 600-650°C |

| Hardening | 950-980°C |

Physical Properties

| 20°C | 100°C | 200°C | 300°C | 400°C | |

|---|---|---|---|---|---|

| Elastic Modulus [kN/mm²] | 207 | - | - | - | - |

| Thermal Expansion Coefficient [10ˉ6/K] | - | 11,5 | 10,9 | 11,3 | 11,6 |

| Thermal Conductivity [W/mK] | 19,4 | - | 24,0 | 26,00 | - |

Delivery Condition

240 HB, Soft annealed.

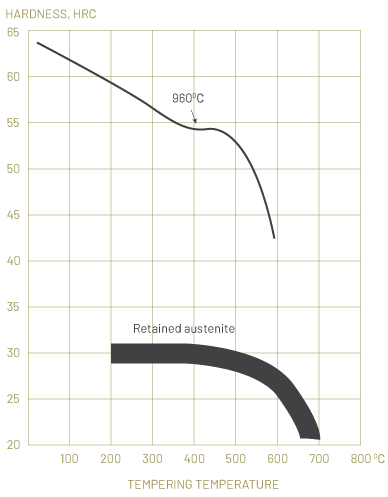

Tempering Graph