V’1.2842

Oil hardened cold work tool steel with high dimensional stability.

Chemical Composition

| NO | DIN | C | Si | Mn | P | S | Cr | V |

|---|---|---|---|---|---|---|---|---|

| V’1.2842 | 90MnCrV8 | 0,85-0,95 | 0,10-0,40 | 1,90-2,10 | Max 0,025 | Max 0,05 | 0,20-0,50 | 0,05-0,15 |

Material Properties

- Very good machinability.

- Very good hardenability with basic heat treatment.

- Very high dimensional stability.

- No secondary hardenability.

- Not suitable for coating.

Applications

- Forming, blanking dies.

- Plastic injection molds.

- Dies support plates.

- Knives, measuring tools

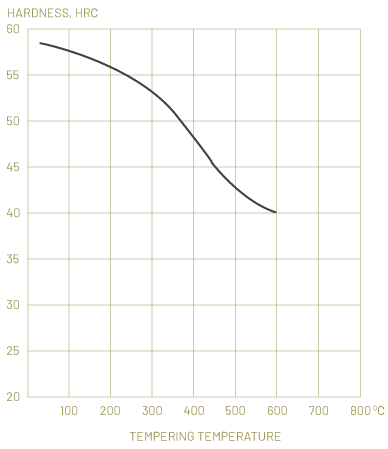

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 680-720°C |

| Stress Relieving | 600-650°C |

| Hardening | 790-820°C |

| Tempering | 180-250°C |

Physical Properties

| 20°C | 100°C | 200°C | 300°C | 500°C | |

|---|---|---|---|---|---|

| Elastic Modulus [kN/mm²] | 210 | - | - | - | - |

| Thermal Expansion coefficient [10ˉ6/K] | - | 12,1 | 13,3 | 13,8 | 14,1 |

| Thermal Conductivity [W/mK] | 33 | - | - | 32,0 | - |

Delivery Condition

230 HB, Soft Annealed.

Tempering Graph