ZAPP Z-Wear PM

Powder metallurgical cold work tool steel that can be easily machined and grinded. According to 1.2379, it is an ideal material for long-lasting cutting and forming dies in difficult conditions with high wear resistance and toughness.

Chemical Properties

| NO | DIN | C | Cr | Mo | V | W |

|---|---|---|---|---|---|---|

| Z-Wear PM | Special Alloy | 1,15 | 7,50 | 1,60 | 2,40 | 0,50 |

Material Properties

- Very high abrasive wear resistance

- Very good adhesive abrasion resistance

- High compression strength

- High toughness

- Easy to process

- Suitable for high temperature tempering

- Suitable for coating with appropriate heat treatment

- Suitable for below zero operation

- Good measurement stability in heat treatment

Applications

- As punch and die in cutting dies

- As punch and mold for cutting and forming AHSS sheets

- In cutting wet steels

- Slice, shear dies and tools

- Pipe profile reel and sets

- In the manufacture of staples and punch

- Smuffing, forming molds

- Beat balls and molds

- Industrial knives

- In hand knives

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 870°C / 2h, Cool slowly at a rate of 15 °C per hour up to 540°C. it can be continued to cool in open air. Result hardness: BHN 225-248. |

| Stress Relieving | 595-700°C / 2h |

| Hardening | Pre-heating: 620-650°C, 810-845°C, 930-955°C austenitizing 1010°C - 1120°C High pressure gas (at least 4 bar pressure) should be cooled up to 700°C. |

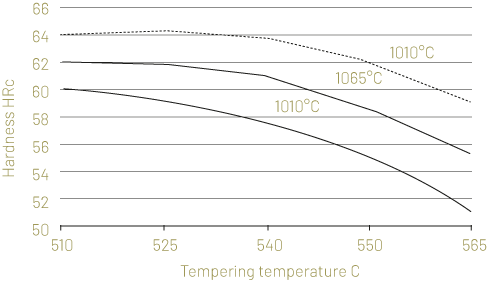

| Tempering | 540-595°C x 2 Tempering If EDM and PVD is to be done, at least 3 times tempering is needed. |

Toughness Values

Delivery Conditions

255 HB, Soft annealed.

Tempering Graph