ZAPP Z 420 PM

Z-420 PM® is a corrosion resistant, high vanadium tooling material produced by powder metallurgy methods. It is a martensitic stainless grade designed to also provide high wear resistance (similar to Z-9 PM) while maintaining good toughness (similar to Z-10 PM).

Chemical Composition

| NO | DIN | C | Cr | V | Mo |

|---|---|---|---|---|---|

| Z 420 PM | Special Alloy | 2,30 | 14,00 | 9,00 | 1,00 |

Applications

- Plastic injection and extrusion feedscrews

- Non-return valve components

- Palletizing equipment

- Injection molds and inserts

- Industrial knives, cutters and slitters

- Wear parts in food and chemical processing

- Gear pumps

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Annealing | Heat uniformly in a protective atmosphere (or vacuum) to 1650°F (890°C) and soak for 2 hours. Slow cool 30°F (15°C) per hour until 1000°F (540°C). |

| Stress relieving | Heat uniformly to 1100–1300°F (595–700°C) soak for 2 hours and cool in air or furnace. |

| Hardening | Vacuum, salt, or protective atmosphere methods are generally used. Care must be taken to prevent decarburization. |

| Tempering | Immediately temper after the material has cooled down below 40°C. CPM® 420 V® is normally tempered through two tempering stages, each of 2 hours duration at 200°C to 400°C. |

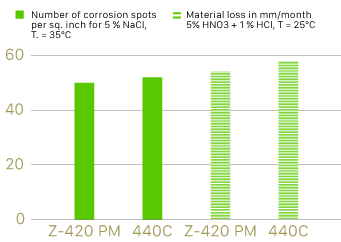

Corrosion Resistance

Delivery Conditions

277- 300 HB

| Required hardness HRC | Austenitizing soak temp. °C | Austenitizing soak time (min) | Tempering temperature °C |

|---|---|---|---|

| 56 | 1065 | 30 | 290 |

| 57 | 1120 | 25 | 40 |

| 58 | 1120 | 25 | 290 |

| 59 | 1175-1180 | 20 | 290 |

* Tempering temperatures from 400 ile 540℃ are not recommended.