V’1.2365

Hot work tool steel with very good creep strength and hot strength.

Chemical Composition

| NO | DIN | C | Si | Cr | Mn | Mo | V | P | S |

|---|---|---|---|---|---|---|---|---|---|

| V’1.2365 | 0,28-0,35 | 0,10-0,40 | 2,70-3,20 | 0,15-0,45 | 2,50-3,00 | 0,40-0,70 | Max 0,025 | Max 0,05 |

Material Properties

- Very high creep strength

- Very high hot strength and tempering back resistance.

- Very good heat checking resistance.

- Good thermal shock resistance.

- Water cooling ability

- Limited toughness (better when oil quenched)

- Limited hardenability

Applications

- Cores and pins in light metals high pressure casting dies.

- Small and symmetric die casting dies also for brass.

- Stamps in light metals such as aluminium copper and brass extrusion dies.

- Forging of light and heavy metals.

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 760-780°C |

| Stress Relieving | 600-650°C |

| Hardening | 1020-1050°C |

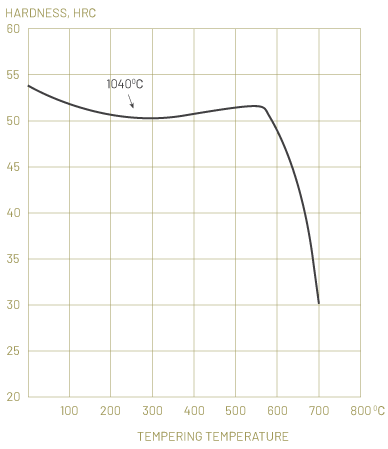

| Tempering | 540-700°C |

Physical Properties

| 20°C | 100°C | 200°C | 300°C | 350°C | |

|---|---|---|---|---|---|

| Elastic Modulus [kN/mm²] | 207 | - | - | - | - |

| Thermal Expansion Coefficient [10ˉ6/K] | - | 12,6 | 13,3 | 13,8 | - |

| Thermal Conductivity [W/mK] | 32,6 | - | - | - | 34,4 |

| Toughness [J] | 21 | - | - | - | - |

| Mukavemet [N/mm²] | 197 | - | - | - | - |

Delivery Condition

Soft Annealed, 225 HB.

Tempering Graph