V’1.2080

Ledeburitic high carbon and chromium (12%) type cold work tool steel with very high wear resistance due to the coarse carbides content.

Chemical Composition

| NO | DIN | C | Si | Mn | P | S | Cr |

|---|---|---|---|---|---|---|---|

| V’1.2080 | X210Cr12 | 1,90-2,20 | 0,10-0,60 | 0,20-0;60 | Max 0,025 | Max 0,05 | 11,00-13,00 |

Material Properties

- It has very high abrasive wear resistance

- High compressive strength

- Limited toughness

- Not suitable for high temperature tempering and coating

- The heat treatment is simple

Applications

- Any application involving abrasive wear.

- Cutting, Blanking dies and tools for thin sheets.

- Industrial knives, shearing tools

- Profile rolls.

- Ceramic tiles molds and powder pressing dies

- Shearing blades for thin sheets.

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft annealing | 800-840°C |

| Stress Relieving | 600-650°C |

| Hardening | 940-970°C |

| Tempering | 200-350°C |

Physical Properties

| 20°C | 100°C | 200°C | 300°C | 400°C | |

|---|---|---|---|---|---|

| Elastic Modulus [kN/mm²] | 210 | - | - | - | - |

| Thermal expansion coefficient [10ˉ6/K] | - | 11,7 | 12 | 12,2 | 12,9 |

| Thermal conductivity [W/mK] | 16,6 | 16.7 | 20,5 |

Delivery Condition

248 HB, Soft annealed.

| MATERIAL | BRINELL HARDNESS | HRc | N/mm2 |

|---|---|---|---|

| 1.2738 | 280-320 | 30-34 | 965-1085 |

| 1.2738 HH | 320-350 | 34-38 | 1085-1200 |

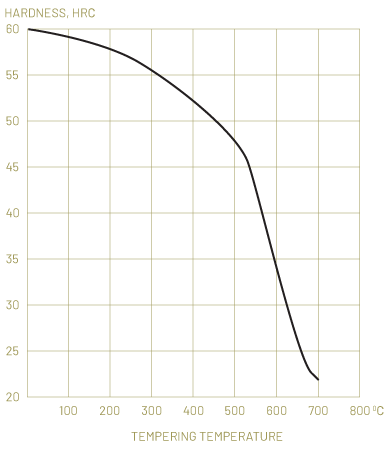

Tempering Graph