– Pre Hardened –

VEGA 40

Pre hardened (40 HRC) modified tool steel for plastic applications with ESR properties. Better cleanliness, homogeneity and polishability than 2738 HH.

Chemical Composition

Special chemical composition.

Material Properties

- High hardness (Prehardened).

- Uniform hardness across the cross-section area.

- Very good homogeneity and cleanliness

- Very good Polishability.

- Very suitable for texturing.

- Good weldability.

- Good machinability even if it is prehardened up to 40 HRc.

- The recommended working hardness is the delivery hardness.

- Very good nitriding and coating ability.

- Very good dimensional stability while nitriding.

Applications

- Cavities and cores in the plastic Injection molds with surface quality up to A1 and A1+:

- Automotive interior trimming dies.

- White goods’ panels.

- Packaging molds.

- Injection molds of transparent parts.

- In extrusion dies of non-corrosive plastics.

- Machinery equipment, wearing plates.

- Plastic pressing, compression dies.

- Use nitriding if the reinforcement more than 20%

Heat Treatment

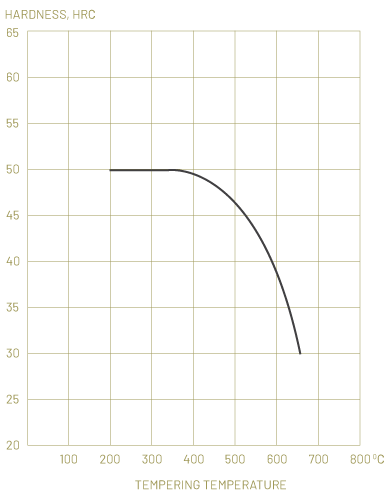

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 710-740°C |

| Stress Relieving | 550-600°C |

| Hardening | 870-900°C |

| Tempering | 560-650°C |

Physical Properties

| 20°C | 200°C | 300°C | |

|---|---|---|---|

| Elastic Modulus [kN/mm²] | 212 | 207 | 194 |

| Thermal Expansion Coefficient [10ˉ6/K] | 11 | 12,5 | 12,8 |

| Thermal Conductivity [W/mK] | 41 |

Delivery Condition and Comparison

| Hardness HB | Hardness HRc | Tensile Strength N/mm2 | |

|---|---|---|---|

| Vega 40 | 350-390 | 38-42 | 1150-1290 |

| 1.2738 HH | 320-350 | 34-38 | 1085-1200 |

| 1.2738 | 280-320 | 30-34 | 965-1085 |

Microstructural Cleanness

ASTHM E45/97 Method: A. Plate: I-R

| A (Sulphide Type) | B (Alumina Type) | C (Silica Type) | D (Globular Oxide Type) | ||||

| T (Thin) | H (Heavy) | T | H | T | H | T | H |

| 0,5 | 0,5 | 0,5 | 0,5 | 0 | 0 | 1,0 | 0,5 |

Tempering Graph