– Stainless Tool Steels –

V’1.2316

It is a pre-hardened plastic mold steel with high corrosion resistance thanks to its 16% Cr content.

Chemical Composition

| NO | DIN | C | Si | Mn | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|---|

| V’1.2316 | 38CrMo16 | 0.33-0.45 | Max 1,00 | Max 1,50 | Max 0,05 | Max 0,025 | 15,50-17,50 | 0,80-1,20 | Max 1,00 |

Material Properties

- Corrosion resistance is very high.

- It has a good taste.

- It is pre-hardened but easy to process (due to S contribution).

- It has optimum abrasion resistance.

- It is not suitable for nitration process.

Applications

- Extrusion and injection molds of corrosive polymers such as PVC,

- As mold holder and calibration block,

- As a mold holder,

- It is used in machine parts.

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 780-820°C |

| Stress Relieving | 600-650°C |

| Hardening | 1000-1040°C |

| Tempering | 600-680°C |

Physical Properties

| 20°C | 100°C | 200°C | 300°C | 400°C | |

|---|---|---|---|---|---|

| Elastic Modulus [kN/mm²] | 205 | - | - | - | - |

| Thermal Expansion Coefficient [10ˉ6/K] | 10,00 | 10,3 | 10,8 | 11,2 | 11,6 |

| Thermal Conductivity [W/mK] | 19,6 | - | - | 21,10 | 20,7 |

Delivery Condition

Pre-hardened 280 – 325 HB (29 – 33 HRC).

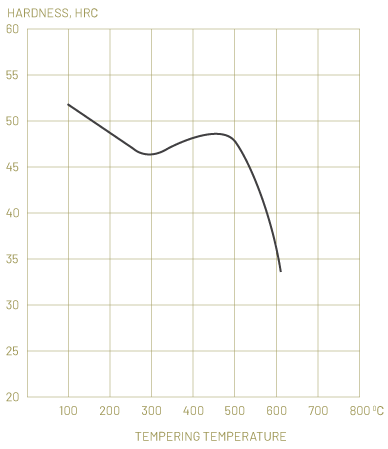

Tempering Graph