– Heat Treatable –

V’1.2083 ESR

ESRed plastic mold steel with perfect polishability and very good corrosion resistant

Chemical Composition

| NO | DIN | C | Si | Cr | Mn | P | S |

|---|---|---|---|---|---|---|---|

| V’1.2083 | X40Cr14 | 0,36-0,42 | Max 1,00 | 12,50-14,50 | Max 1,00 | Max 0,025 | Max 0,05 |

Material Properties

- Very good corrosion resistance.

- Good wear resistance.

- Excellent polishability and surface finish.

- Good machinability.

- Heat treatable up to 52 HRc.

- Limited texturing and nitriding ability.

- Good coating ability.

- High wear resistance.

Applications

- Molds and tools for corrosive environment

- Small to medium sized cavities and cores used for molding corrosive plastics like PVC

- Molds working in humid environment

- Core and cavities for long production runs with high gloss surface finish

- Widely used in dies requiring mirror like surface finish (A1+).

- Medical and optical industry such as spectacles and lenses.

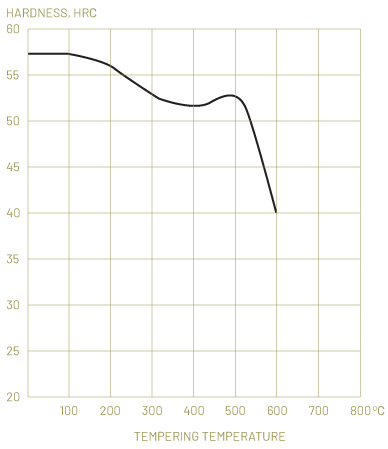

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 760-800°C |

| Stress Relieving | 600-650°C |

| Hardening | 1000-1050°C |

| Tempering | 200-550°C |

Physical Properties

| 20°C | 100°C | 200°C | 300°C | 400°C | |

|---|---|---|---|---|---|

| Elastic Modulus [kN/mm²] | 220 | - | - | - | - |

| Thermal expansion coefficient [10ˉ6/K] | - | 10,5 | 10,9 | 11,3 | 11,6 |

| Thermal conductivity [W/mK] | 22 | - | 24 | 26 | - |

Delivery Condition

241 HB, Soft Annealed

Tempering Graph