– Heat Treatable –

1.2344 VEXtra

Hot work tool steel with ESR properties. Good combination of hot strength and toughness and also hot wear resistance.

Chemical Composition

| NO | DIN | C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|---|---|

| V’1.2344 | X40CrMoV5-1 | 0,35-0,43 | 0,80-1,20 | 0,25-0,50 | Max 0,02 | Max 0,005 | 4,80-5,50 | 1,20-1,50 | 0,85-1,15 |

Material Properties

- Good hot strength and tempering back resistance.

- Resistant to thermal shock

- Very high toughness and ductility.

- Good weldability

- Good machinability

- Up to 54 HRc after heat treatment

- The recommended working hardness 44-52

- Good nitriding and coating ability

Applications

- Aluminium extrusion dies, support blocks, bolster, stamp, staples, sealed cores.

- Secondary areas in die casting dies such as biscuit and runner,

- Shot Sleeve in HPDC

- Any type of press forging applications.

- High wear resistant and hard (48 HRc) dies for large production number.

- Upper and also bottom dies in low pressure die casting.

- Gravity molds.

- Industrial knives.

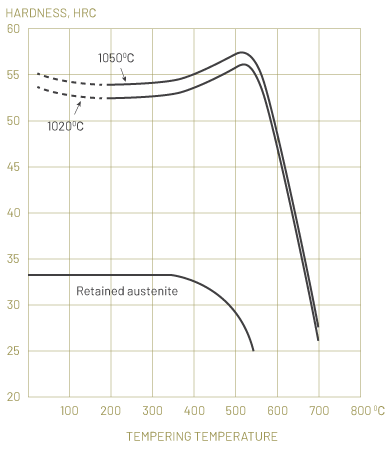

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 820-860°C |

| Stress Relieving | 600-650°C |

| Hardening | 1020-1060°C |

| Tempering | 530-700°C |

Physical properties

| 20°C | 100°C | 400°C | 500°C | 600°C | |

|---|---|---|---|---|---|

| Elastic Modulus [kN/mm²] | 215 | - | 179 | - | 168 |

| Thermal Expansion Coefficient [10ˉ6/K] | - | 10,7 | 11,0 | - | 13 |

| Thermal Conductivity [W/mK] | 26 | - | 27,9 | 28,5 | 29,3 |

Delivery Condition

230 HB, Soft annealed.

Tempering Graph