Sirio® VAR

VAR (Vacuum Arc Remelted) and modified 1.2367 Hot Work Tool steel with excellent hot properties and ductility designed for tough conditions.

Chemical Composition

| No | ~W. No | C | Si | Cr | Mo | V | Diğer |

|---|---|---|---|---|---|---|---|

| Sirio® VAR | 1.2367 Mod VAR | 0,32 | 0,2 | 5,1 | 2,35 | 0,55 | + |

Material Properties

- Excellent hot strength and tempering back resistance.

- Very good creep resistance

- Very good heat checking resistance.

- High Toughness and ductility.

- Very good thermal shock resistance.

- Excellent cleanliness

- Good Weldability,

- Good machinability.

- Up tp 54 HRc after heat treatment

- Recommended working hardness 44-52 HRc.

- Good nitriding and coating ability

Certificate

Highly certified grade, and many properties’ quality is guaranteed by the certifying supplier company such as toughness, microstructure cleanness and many more.

Applications

- Long life die casting dies, cores, cavities and inserts.

- Die casting dies:

- Against to thermal fatigue cracks

- Against to gross cracking

- If there is a high velocity in the runner and also inside the cavity

- If it is matter of wall thickness and complex geometry.

- Dies with complex geometry.

- If it is very cosmetic Al part

- PVD coated insert against to soldering.

- Cores in press forging dies.

- Warm forging dies.

- Hot stamping dies.

- Aluminum extrusion dies and tools.

- Preferred for dies and tools operating at high temperatures.

- Punches, cutting and shearing blades thicker than 10 mm.

- Cold forging and cold extrusion dies.

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 630-800°C |

| Stress Relieving | 600-650°C |

| Hardening | 1000-1050°C |

| Tempering | 530-700°C |

Physical Properties

| 20°C | 400°C | 500°C | |

|---|---|---|---|

| Elastic Modulus [kN/mm²] | 205.000 | 190.000 | |

| Thermal Expansion Coefficient [10ˉ6/K] | 12,4 | 13,2 | |

| Thermal Conductivity [W/mK] | 21 | 30 | 32 |

Mechanical Properties

| 44 Hrc | 48 Hrc | 50 Hrc | |

|---|---|---|---|

| Yield Strength Rp02 [N/mm²] | 1200 | 1400 | 1500 |

| Tensile Strength, Rm | 1500 | 1680 | 1800 |

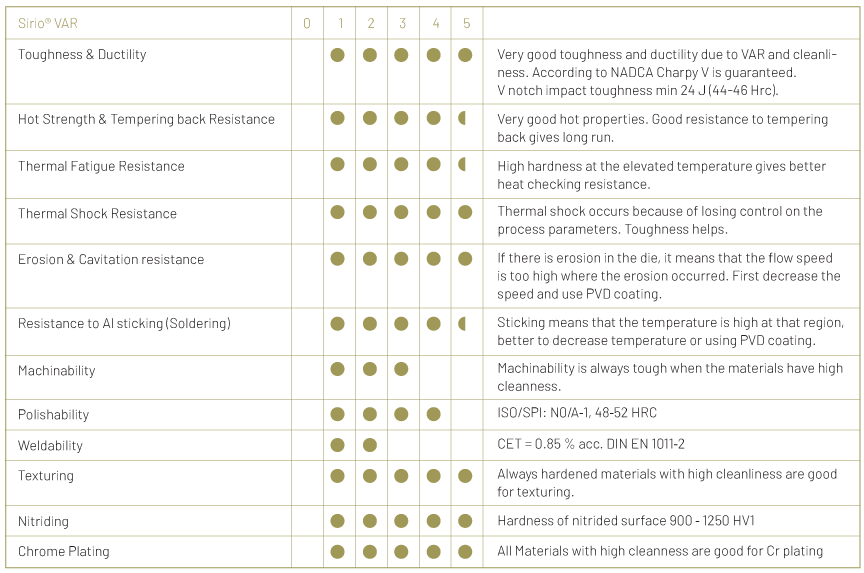

Properties

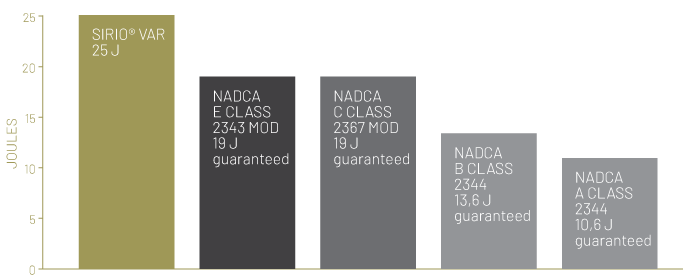

Toughness Value

Impact resistance values obtained from samples oil hardened to 44-46 HRc and twice tempered:

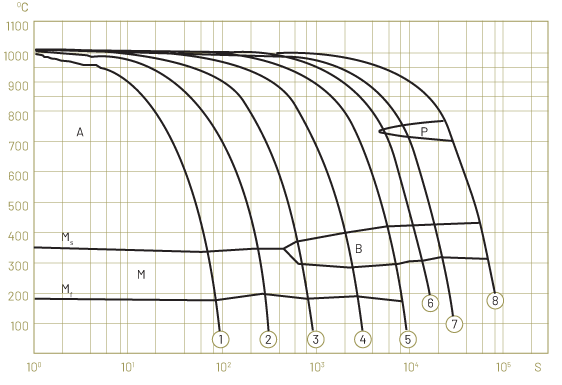

Continuous Cooling Diagram

Delivery Condition

Max. 220 HB, Soft Annealed.

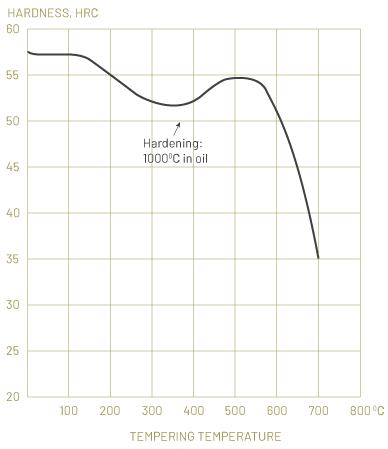

Tempering Graph