1.2714 VEXtra

Impact resistant hot work tool steel for hammer forging.

Chemical Composition

| NO | DIN | C | Si | Mn | P | S | Cr | Mo | V | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| V’1.2714 | 55NiCrMoV | 0,50-0,60 | 0,40-1,10 | 0,65-0,90 | Max 0,025 | Max 0,050 | 1,00-1,20 | 0,45-0,55 | 0,07-0,12 | 1,60-1,80 |

Material Properties

- Excellent toughness.

- Very good hardness profile

- Good machinability.

- Not recommended to use on applications more than 44 HRc.

Applications

- Press forging: Medium and large size forging dies.

- Core and cavities for press forging

- Support parts and holders in forging dies.

- Bolsters and support blocks on aluminium extrusion dies.

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 690-730°C |

| Stress Relieving | 600-650°C |

| Hardening | 860-900°C |

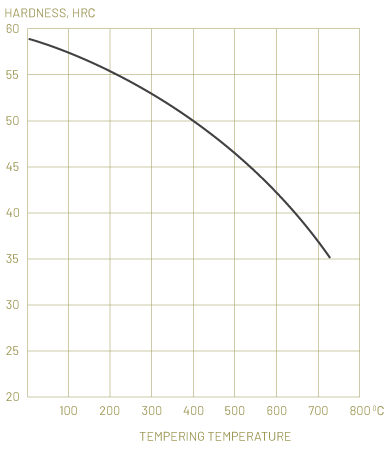

| Tempering | 300-600°C |

Physical properties

| 20°C | 100°C | 200°C | 400°C | 600°C | |

|---|---|---|---|---|---|

| Elastic Modulus [kN/mm²] | 210 | - | - | 198 | 178 |

| Thermal Expansion Coefficient [10ˉ6/K] | 12 | 12,1 | 13,1 | 13,5 | 14,3 |

| Thermal Expansion [W/mK] | 36,0 | - | 37,0 | 39,0 | 36,0 |

| Toughness [J] | 25,0 | 36,0 | 39,8 | - | - |

| Strength [N/mm²] | 1150 | - | 1030 | 930 | - |

Delivery conditions

Prehardened: 40-44 HRc Only Flats and blocks

Soft annealed 250 HB: Only Rounds

Tempering graph