Prehardened plastic mold steel, also known as P20, prehardened (30-33 HRc) with good machinability and polishability for fast mold making.

Chemical Composition

| NO | DIN | AISI | C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|---|---|---|

| V’1.2311 | 40CrMnMo7 | P20 | 0,35-0,45 | Max 0,80 | 1,30-1,60 | Max 0,02 | Max 0,005 | 1,80-2,10 | 0,15-0,25 |

Material Properties

- Homogeneous hardness distribution along the cross section up to 300 mm thickness.

- Better Polishability compare to 2312 (P20+S)

- Good weldability.

- High Toughness.

- Good machinability even if it is prehardened.

- The preferred working hardness is the delivery hardness.

- Good nitriding and chrome planting ability.

- Up to A2 Surface quality.

Applications

- Cores and cavities in plastic injection mould

- Small or medium sizes injection molds

- Pressure casting dies

- Mold frames for plastic molds

- Extension dies for thermoplastics

- Dies of light alloys with low melting point

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 700-720°C |

| Stress Relieving | 600-650°C |

| Hardening | 870-900°C |

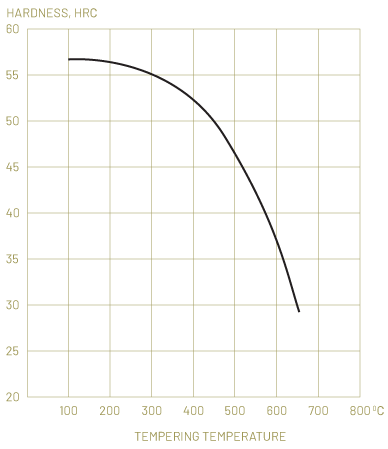

| Tempering | 600-680°C |

Physical Properties

| 20°C | 100°C | 200°C | 300°C | |

|---|---|---|---|---|

| Elastic Modulus [kN/mm²] | 205 | - | - | - |

| Thermal Expansion Coefficient [10ˉ6/K] | - | 11,5 | 11,6 | 12,5 |

| Thermal Conductivity [W/mK] | - | 34,00 | 33,6 | 31,9 | Toughness [J] | 30,5 | - | - | - | Strength [N/mm²] | 844,5 | - | - | - |

Delivery Condition

Prehardened, 280-320 HB

Tempering Graph