Quenched and Tempered steel widely used in the manufacturing of machines and die making due to its high tensile strength and toughness.

Chemical Composition

| NO | Malzeme No | DIN | C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|---|---|---|

| V’4140 | 1.7225 | 42CrMo4 | 0.38-0.45 | Max 0,40 | 0,75-1,0 | Max 0,035 | Max 0,035 | 0,90-1,20 | 0,15-0,35 |

Material Properties

- Very good toughness.

- Suitable for quenching and tempering.

- Good flame and induction hardenability

- Good nitriding ability.

- Simple heat treatment.

Applications

- All dies stands and holders.

- Support plates.

- Basic plastics injection molds.

- Crank arms, Axle shaft and sleeve.

- Constructions and agricultural machinery.

- Bolts, nuts, and studs

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 680-750°C |

| Stress Relieving | 600-650°C |

| Hardening | 830-870°C |

| Tempering | 540-680°C |

Delivery Condition

Can be supplied as prehardened 28-34 HRc

Or Soft Annealed.

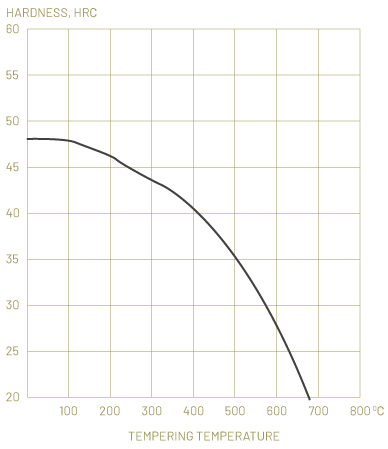

Tempering Graph