Ledaburitic cold work took steel, with high abrasive wear resistance due to the Tungsten and Chromium (12%) content.

Chemical Composition

| NO | DIN | C | Si | Cr | Mn | W | P | S |

|---|---|---|---|---|---|---|---|---|

| V’1.2436 | X210CrW12 | 2,00-2,30 | 0,10-0,40 | 11,00-13,00 | 0,30-0,60 | 0,60-0,80 | Max 0,025 | Max 0,05 |

Material Properties

- Excellent abrasive wear resistance

- Better hardenability comparing to 1.2080

- Limited toughness

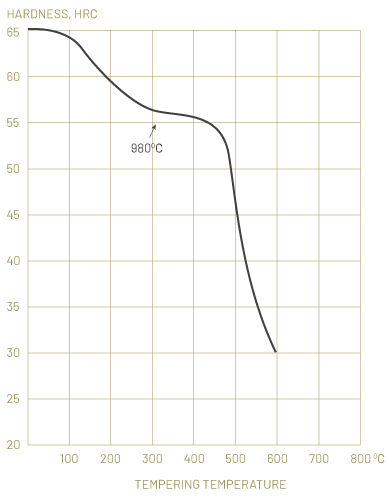

- No secondary peak at tempering

- Not suitable for coating

Applications

- Abrasive powders pressing dies

- Ceramics, tiles molds

- Sheet metal cutting and bending dies

- Forming rolls

- Blanking dies of silicon sheets

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 800-840°C |

| Stress Relieving | 600-650°C |

| Hardening | 960-980°C |

| Tempering | 200-550°C |

Physical Properties

| 20°C | 100°C | 400°C | 500°C | 600°C | |

|---|---|---|---|---|---|

| Elastic Modulus [kN/mm²] | 215 | - | 179 | - | 168 |

| Thermal Expansion Coefficient [10ˉ6/K] | - | 10,7 | 11,0 | - | 13 |

| Thermal Conductivity [W/mK] | 26 | - | 27,9 | 28,5 | 29,3 |

Delivery Condition

255 HB, Soft Annealed.

Tempering Graph