– Mold Holders –

V’1.2312

Prehardened (30-33 HRc) plastic mold steel known as P20+S with very good machinability due to the sulphur content.

Chemical Composition

| NO | DIN | AISI | C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|---|---|---|

| V’1.2312 | 40CrMnMoS8-6 | P20+S | 0.35-0.45 | 0.20-0.50 | 1.30-1.60 | Max 0,025 | 0,10-0,50 | 1.80-2.10 | 0.15-0.25 |

Material Properties

- Very good machinability even if it is prehardened.

- Perfect for gun drilling and rapid drilling

- Perfect for fast milling

- Great hardness homogeneity along the cross-section area up to 300 mm thickness.

- Not suitable for mirror polishing, texturing

- Weak weldability

- The recommended working hardness is the delivery hardness.

- Good nitriding ability.

Applications

- All kind frames and holders for molds and dies

- Plastic injection mould cores and cavities (not cosmetic parts)

- Plastic injection mould cores (not cosmetic sides)

- Die casting die holders

- Machinery equipment.

- Wearing Plates.

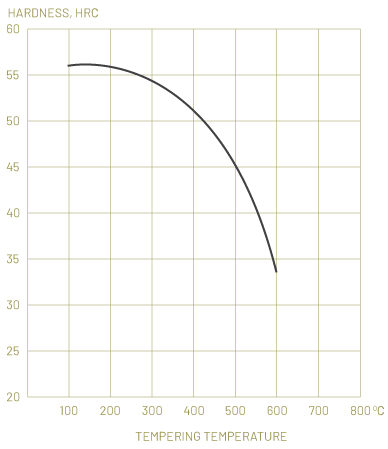

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 700-750°C |

| Stress Relieving | 550-650°C |

| Hardening | 830-870°C |

| Tempering | 600-680°C |

Physical Properties

| 20°C | 100°C | 200°C | 300°C | |

|---|---|---|---|---|

| Elastic Modulus [kN/mm²] | 210 | - | 195 | - |

| Thermal Expansion Coefficient [10ˉ6/K] | - | 12,1 | 12,7 | 13,2 |

| Thermal Conductivity [W/mK] | 34,0 | 35.0 | 35.6 | 36,4 |

| Toughness | 20 | - | - | - |

| Strength [N/mm²] | 850 | - | - | - |

Delivery Condition

Prehardened, 280-320 HB.

Tempering Graph