Astro® ESR

ESR (Electro Slag Remelting) hot work tool steel with very good toughness and cleanliness.

Chemical Composition

| NO | DIN | C | Si | Cr | Mo | V | Mn | P | S |

|---|---|---|---|---|---|---|---|---|---|

| 1.2343 ESR | X37CrMoV5-1 | 0,33-0,41 | 0,80-1,20 | 4,80-5,50 | 1,10-1,50 | 0,30-0,50 | 0,25-0,50 | Max 0,01 | Max 0,003 |

Material Properties

- High toughness and ductility.

- Very good microstructural cleanliness and homogeneity.

- Very good Polishability.

- Good hot strength and tempering back resistance.

- Very good texturing ability.

- Good weldability.

- Good machinability.

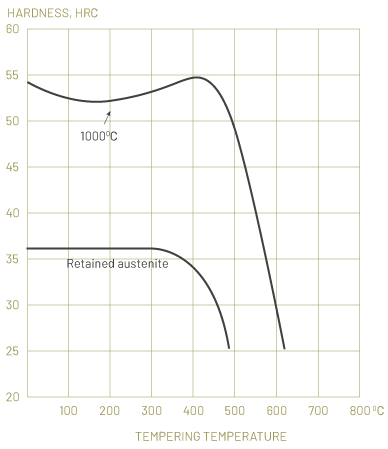

- Up to 54 HRc after heat treatment.

- Recommended working hardness 44-52 HRc.

- Good nitriding and coating ability.

Applications

- Precision Plastic injections molds,

- High gloss plastic injection moulds,

- Molds for piano black surfaces such as headlights lens molds.

- Molds for abrasive polymers and reinforced resins.

- Die casting dies for medium run

- Die casting dies of lighting and other large parts.

- Secondary sections on high pressure die casting dies for long run.

- Dies for all press forging applications.

- Cutting and shearing blades thicker than 10 mm.

- Cold forging and cold extrusion dies.

- Industrial knives resistant to ductile fracturing and breaking risks.

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 750-800°C |

| Stress Relieving | 600-650°C |

| Hardening | 1020-1060°C |

| Tempering | 530-700°C |

Physical Properties

| 20°C | 100°C | 400°C | 500°C | 600°C | |

|---|---|---|---|---|---|

| Elastic Modulus [kN/mm²] | 210 | - | 183 | 176 | 168 |

| Thermal Expansion Coefficient [10ˉ6/K] | - | 10,7 | 11,8 | 11,9 | 12,4 |

| Thermal Conductivity [W/mK] | - | 28,4 | 27,1 | 29,9 | 28,5 |

Delivery Condition

230 HB, Soft annealed.

Tempering Graph