Altair® VAR

VARed (ESR in vacuum) modified hot work tool steel with excellent toughness.

Chemical Composition

| NO | ~W. No | C | Si | Cr | Mo | V |

|---|---|---|---|---|---|---|

| Altair VAR | 2340 Mod VAR / 2343 Mod VAR | 0,36 | 0,2 | 5,0 | 1,40 | 0,50 |

Material Properties

- Excellent toughness and ductility,

- Very good thermal checking resistance

- High hot strength and tempering back resistance.

- Very good thermal shock resistance.

- Excellent cleanliness

- Good weldability.

- Good machinability.

- Up to 54 HRc after heat treatment.

- Recommended working hardness 44-52 HRc

- Good nitriding and coating ability.

Certificate

Highly certified grade, and many properties’ quality is guaranteed by the certifying supplier company such as toughness, microstructure cleanness and many more.

Applications

- Preferred for all dies and tools requiring high toughness and ductility

- Cores and cavities for long run die casting dies.

- Die casting dies:

- Complex geometries.

- Sections subjected to breaking risks.

- Against to thermal fatigue cracks.

- Dies and Cores in press forging dies,

- Warm forging dies.

- Precision Plastic injections molds,

- High gloss plastic injection moulds,

- Molds for piano black surfaces such as headlights lens molds.

- Molds for abrasive polymers and reinforced resins.

- Cutting and shearing blades thicker than 10 mm.

- Cold forging and cold extrusion dies.

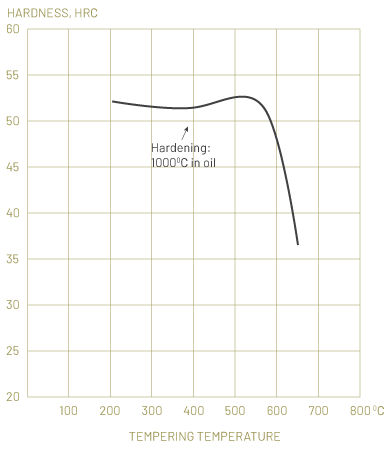

Heat Treatment

| HEAT TREATMENT | TEMPERATURE |

|---|---|

| Soft Annealing | 740-780°C |

| Stress Relieving | 600-650°C |

| Hardening | 1000-1030°C |

| Tempering | 550-650°C |

Physical Properties

| 20°C | 400°C | 600°C | |

|---|---|---|---|

| Elastic Modulus [kN/mm²] | 205.000 | 175.000 | 145.000 |

| Thermal Expansion Coefficient [10ˉ6/K] | 11,8 | 12,7 | 12,9 |

| Thermal Conductivity [W/mK] | 29 | 30 | 33 |

Mechanical Properties

| 44 Hrc | 48 Hrc | 50 Hrc | |

|---|---|---|---|

| Yield Strength Rp02 [N/mm²] | 1200 | 1400 | 1500 |

| Tensile Strength, Rm | 1500 | 1680 | 1800 |

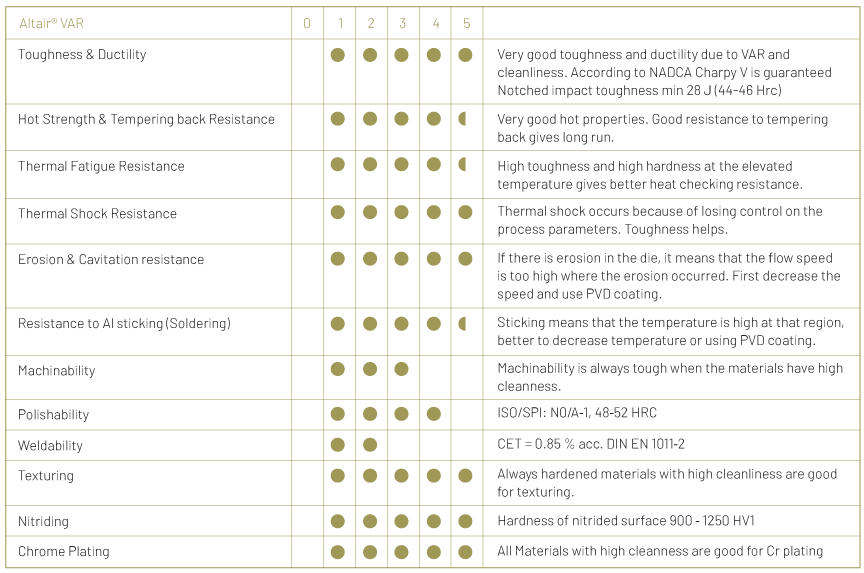

Properties

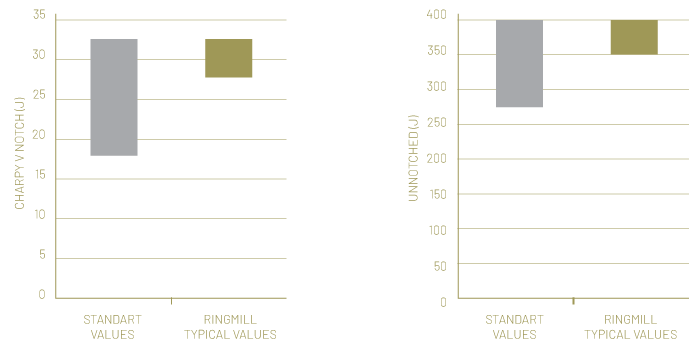

Toughness values

Impact resistance values obtained from samples oil hardened to 44-46 HRc and twice tempered:

| Test | Bölge | Isı | Ortalama |

|---|---|---|---|

| KV | External zone | 20°C | 28 (Joule) |

| KV | Core zone | 20°C | 28 (Joule) |

| KVW | External zone | 20°C | 380 (Joule) |

| KVW | Core zone | 20°C | 365 (Joule) |

Delivery Condition

Max. 220 HB, Soft Annealed.

Tempering Graph